Walnut Blast Media

Walnut Blast Media

FEATURES

The term “abrasive media” is most often associated with harder, manmade materials such as steel shot or grit, silicon carbide or aluminum oxide. However, certain metal finishing applications require a softer, less abrasive material that can deliver the desired result without the risk of damage to the substrate surface.

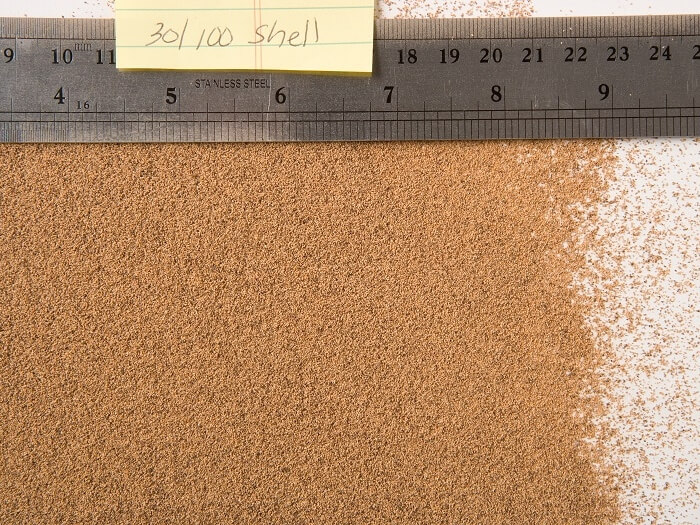

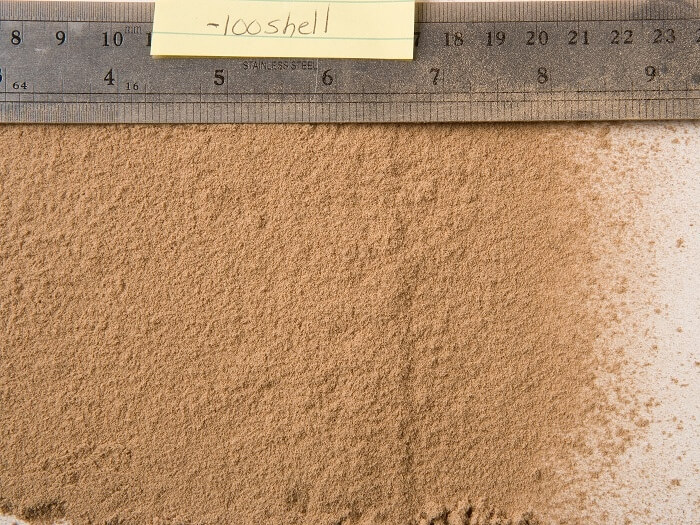

Crushed black walnut shells offer a softer, gentler media blasting alternative to these harsher materials. Specifically intended for use in dry air blasting applications, walnut shells are a lightweight, angular media that will effectively remove topcoats while leaving undercoating intact.

Prior to the introduction of walnut shell media blasting, metal finishers typically had to resort to stripping coatings down to the bare metal and completely replacing the under-coatings and topcoat. Walnut shell blasting eliminates the need for these costly, time-consuming processes.

inquire about this product