Vibratory Deburring or Mass Finishing, as it is commonly referred, was introduced commercially in 1957 and is now considered the mainstay of the deburring industry. This manufacturing process is frequently employed to impart a specific finish or remove an undesired burr onto a metal or plastic component.

The process occurs in a specially designed vibratory deburring and finishing machine, which is often referred to as a tumbler. The tumbler is filled with a chemical compound and vibratory tumbler polishing media. The vibratory machine or tumbling barrel is charged with the appropriate media based on the finish required. Water is also introduced to the vibrating and tumbling mass of media and parts — to further assist in lubricating and cleaning. The parts are then fully submerged in the solution. The activation of the vibratory deburring machine causes the submerged parts to move in a circular direction, which forces the parts, media and treated water to rub against each other. This produces the desired finishing result.

When properly executed, vibratory finishing will provide a number of valuable benefits. The process offers an extremely cost-effective means for deburring, polishing, descaling, cleaning and a host of other surface preparation and finishing solutions, while requiring a minimal amount of labor. It also results in an extremely smooth surface finish without causing extensive wear, which increases the finished product’s durability. What’s more, the process is highly controllable, making it easier to achieve a uniform finishing result.

Vibratory finishing is an extremely flexible process that offers numerous design possibilities. With the appropriate use of vibratory deburring/polishing machines, it is relatively easy to create a customized procedure for one-part systems where each part is processed individually; for batch systems where sets of parts are processed and removed prior to the addition of the subsequent batch; for continuous systems such as a conveyor belt-type of operation; and a sequenced process consisting of multiple finishing steps.

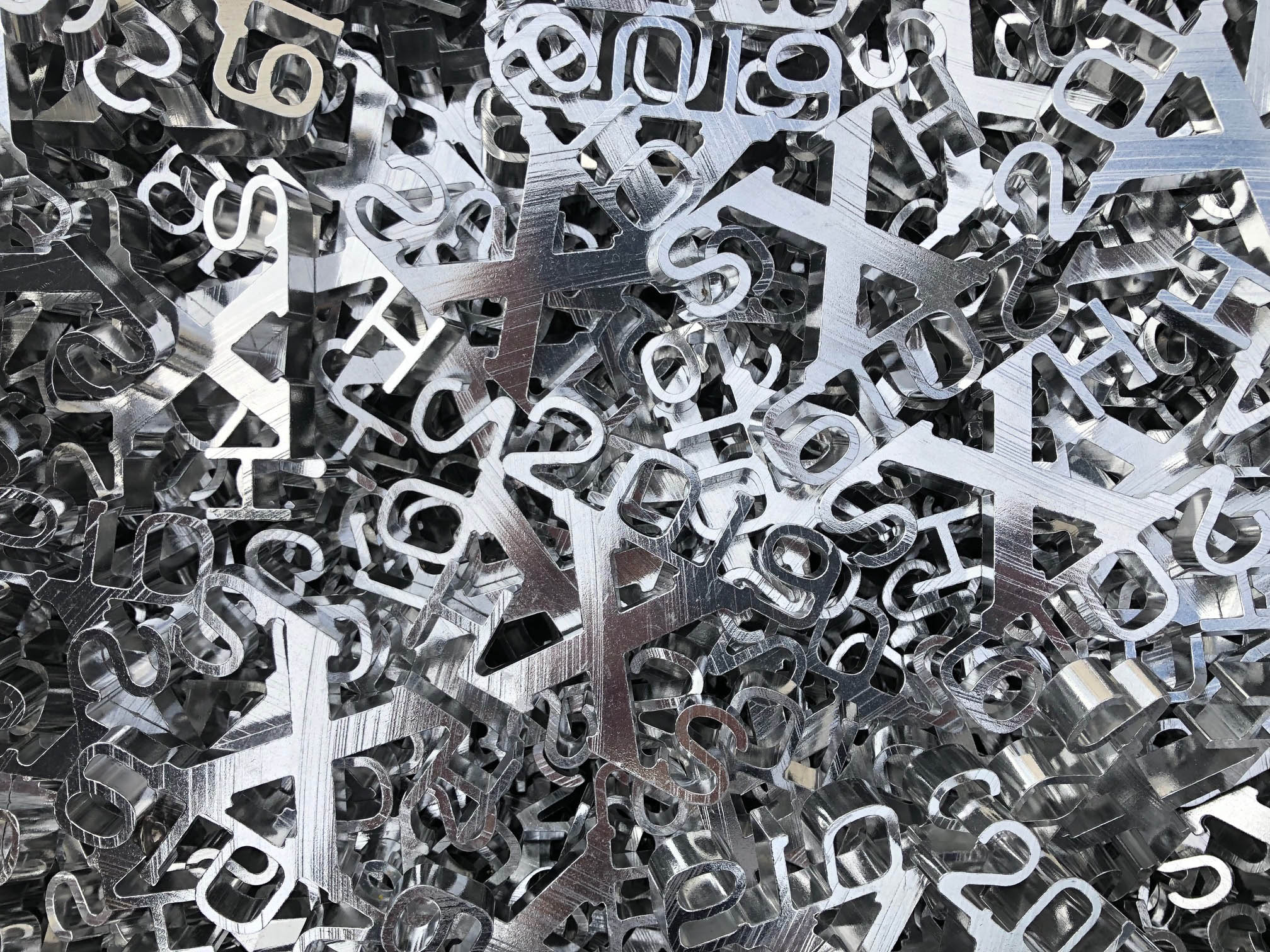

Regardless of the desired outcome, the success of the vibratory process is insured by the proper selection of media and a cleaning compound. Select media based on the correct composition, size, shape and dimension to produce the desired finish for the job. Finishing Systems has the expertise to ensure that these critical steps are executed properly. Our experience allows us to properly choose the size and configuration of media to ensure that lodging is avoided and your parts are finished to your specifications.

We inventory a vast supply of finishing media for use in our own shop as well as for distribution. This inventory is comprised of a variety of sizes, shapes and compositions for any application. Of course should your application warrant your own in-house mass finishing equipment Finishing Systems carries a complete line, as well as the media and chemical compounds. You can be sure of finding the best vibratory polishing media for aluminum or any other material.

In addition to the appropriate media selection, it takes the right equipment to execute any vibratory finishing process. Finishing Systems is your headquarters for a wide variety of vibratory deburring and finishing machines for use in just about any mass finishing process. Options include round and spiral bowl finishers, combo finisher/dryers and long radius finishing equipment. As with our finishing media, we can help you choose the right machine for your process requirements. Additionally, we can work with you to design and implement the best process for your unique manufacturing requirements.

The customer service is fantastic, their crew does a great job of getting back to you on quotes, process time, etc. in a very timely manner. Their quality is A+. One of the greatest vendors Epy Industries has the pleasure of working with.

In business since 1972, York, PA-based Finishing Systems has developed a stellar reputation as one of the leading metal finishing companies in the industry. Our ability to provide superior products and a host of specialized support services has made us a top choice for companies in industries such as auto manufacturing, heavy equipment manufacturing and many others. We have a proven track record of producing reliable, cost-effective solutions for companies in our local area, as well as across the United States and around the world.

Contact Finishing Systems today to learn more about our vibratory finishing products and services.

Contact Us