Abrasives and Sandblasting Equipment

Blast finishing offers the flexibility to remove many different types of surface imperfections, including burrs, rust, scales, paint removal and more. In addition, abrasive blasting can etch a surface to adequately prepare it for a final finish such as paint or powder coating. Finishing Systems stocks a vast inventory of many different types of abrasive blasting media for use in the pressure blasting and wheel blasting processes. And finally, should you not have the equipment or be interested in your own in-house blasting, we offer a comprehensive job shop in York, PA, in which we can do your blasting for you.

We have both air blast and centrifugal wheel blasting systems for your in-house abrasive finishing needs.

Air Blast Equipment

Our air blasting equipment efficiently finishes your metal parts by using high-pressure compressed air to propel loose abrasive blast media over the surface of the part. This is one of the most common and effective methods for part abrasion. Our air blast equipment includes:

- Air blast rooms – Fully control your abrasive finishing environment with these recycling-enabled blast rooms.

- Air blast tumble equipment – Tumble blast machines with a rubber-lined chamber and oscillating nozzles. Available in a variety of sizes.

- Blast cabinets – Either suction-feed or direct pressure-style cabinets.

- Bulk blasting systems – Keep in one location or mount on a trailer for transport.

- Blast and recovery systems – A complete blast system that vacuums as it blasts to contain discarded coatings, rust or other unwanted material waste.

- Cryogenic deflashing systems – Suitable for a range of components, including those made from materials such as zinc, magnesium, rubber, plastic and diecast metal.

- Portable blasting systems – Available in a variety of sizes for your convenience and maximum efficiency. We offer custom package systems that can include add-ons such as respiratory accessories, remote controls and various useful safety features.

- Wet blast equipment – For wet surface finish treatment to get rid of frictional heat using scrubbing rather than dry blasting for abrasion.

Wheel Blast Equipment

Wheel blasting involves the use of steel grit or steel shot blasting media and a special wheel that is turned using centrifugal force. As the wheel turns, it propels the abrasive media from the blades of the wheel to the surface of the part being finished, resulting in a thorough and effective abrasion process.

Our wheel blast equipment includes:

- Cylinder blasters – For removing rust or paint from cylinders.

- Hanger blast equipment – A trolley-mounted blast system.

- Spinner hangers – For effective unloading and loading over a simultaneous blasting cycle.

- Swing table blast equipment – With a swing-out loading and unloading process table included.

- Tumble blast equipment – Abrasive recycling and continuous blast cycles. Choose rubber belt or steel flight.

- Table blasters – Featuring a fixed rotating table in the blast cabinet.

Abrasive Blasting Media Materials

Finishing Systems offers a range of abrasive blasting media to support your operational needs and fit different types of projects. We can help you handle various finishing requirements efficiently while helping you get an optimized final result. Whether you’re looking for crushed glass blasting media, sandblasting material or a range of solutions, we have a broad inventory of options for you.

Our blasting menthod offerings include:

- Glass beads

- Steel shot and grit

- Aluminum oxide and silicon carbide

- Starblast

- Plastics

- Walnut shells and corn cobs

We provide abrasive blasting media options that are environmentally safe, available in multiple grit options and ideal for delivering a smooth finish to your materials. You can find the best fit for the specific materials you’re finishing with trusted support from our team.

Glass Beads

For cleaning, finishing, peening and deburring applications:

- Environmentally safe

- Chemically inert; no ferrous or other residues

- Contains no free silica

- Economical – may be reused/recycled several times

- Provides a uniquely matte, bright surface finish

- Samples available

- Cleans quickly and efficiently without significant metal removal

- Imparts a controlled, clean finish on a variety of metals.

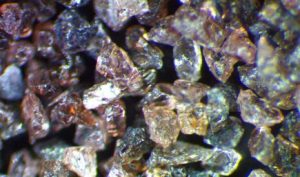

Steel Shot and Grit

For surface preparation, stone cutting and shot peening applications:

- Removal of surface contaminants

- Surface preparation providing a surface profile (etch, matte, finish or anchor pattern)

- Economical and recycled several times

Finishing Systems is proud to distribute Metaltec Steel Abrasive Company and their premium BAINITE Steel Shot. BAINITE’s low carbon cast steel shot blasts the competition away. Stocked in York our steel shot and grit is available in a range of sizes. Steel shot is spherical in shape and comes in a variety of sizes and hardness levels. Steel grit is formed by crushing steel abrasive to produce sharp angular edges.

Metaltec is the only American manufacturer to succeed in producing unique bainite microstructure abrasives that meet SAE specifications for low carbon cast steel shot. Repeatedly, comparative testing has shown BAINITE shot wears better and lasts longer than martensitic cast steel shot.

Today, Metaltec’s Bainite shot is revolutionizing blast cleaning and peening processes in plants throughout North America, and Finishing Systems is proud to be an authorized representative.

Aluminum Oxide and Silicon Carbide

Great for cutting into almost any type of material:

- Abrasive blasting

- Grinding

- Lapping

- Deburring

- Tumbling

- Refractories

- Buffing compounds

- Etching

- Non-slip surfaces

- Fluidized beds

- Plasma spray

Aluminum oxide and silicon carbide are primarily used in pressure blasting applications where heavier cutting is required. Screened and sized to meet industry standards this abrasive blasting media is also economical, making it a preferred choice for general industrial operations.

Aluminum Oxide presents an excellent cost/benefit relationship due to the blending of a tough sintered bauxite with an equally tough fused Brown Aluminum Oxide. Aluminum Oxide has no free iron or free silica and offers a largely dust-free operation.

Starblast®

Starblast, a product of DuPont’s Titanium Technology product lines, is a blasting abrasive characterized by a loose blend of uniformly sized coarse and fine staurolite sands comprised of clean and rounded surfaces. This uniform sizing results in a more consistent blasting pattern. Available in a variety of grades: Starblast™, Starblast™ XL, and Starblast™ Ultra.

It is a general-purpose staurolite abrasive used in steel fabrication and bridge maintenance to remove rust, mill scale and weathered coatings.

Plastics

Plastic abrasive blasting offers a less harsh alternative when working with softer materials that are more susceptible to damage. Thus, plastics are often the choice for applications such as paint removal, deflashing and screw and mold cleaning where metal removal is prohibited and limited.

Walnut Shells and Corn Cobs

As with plastics, walnut shells and corn cobs are used when a softer material is required. As naturally occurring abrasives they are also viewed as a more environmentally-friendly alternative to  other types of abrasive blasting media. Cobs may also be used in the drying process during mass finishing. Walnut shell is a more angular shell abrasive, offering a slightly more aggressive blasting process while metal loss is a consideration.

other types of abrasive blasting media. Cobs may also be used in the drying process during mass finishing. Walnut shell is a more angular shell abrasive, offering a slightly more aggressive blasting process while metal loss is a consideration.

Learn More About Walnut Shells

Other Mass Finishing Abrasive Media Materials

If you’re looking for reliable mass finishing supplies, you can turn to Finishing Systems as your source for a wide range of products. Our offerings include preformed plastics, porcelain media and other specialized solutions. Additionally, we can also provide steel burnishing media in several sizes and shapes. You can also leverage abrasive media optimized for your applications with our sintered ceramic tumbling nugget, the Duralum® XM ‘Coloring’ Abrasive.

Whatever you need to supply your work, we’re here to help with high-performance solutions through our wide-ranging inventory. Choose a leading provider for your abrasive materials to successfully complete large- or small-scale projects at the work site.

Abrasive Blasting Applications for Your Business

With our air blast equipment, you can get quality finishing results for a range of project needs. Our solutions can provide enhanced paint or coating adhesion when you use air blasting prior to application. Some of the ways you can use our blasting selections include:

- Degreasing: Efficiently and thoroughly degrease surfaces before applying coatings to improve overall durability.

- Shot peening: Use our abrasive blasting solutions to extend parts’ service life and optimize performance.

- Cleaning: Before applying coatings, fully clean and prepare the surface for finishing with abrasives to achieve better adhesion.

- Stripping: If you need to prepare your material for finishing, you can strip paint or other coatings for a fresh surface.

- Contaminant removal: Fully remove potential contaminants from the material’s surface for safe and successful preparation.

Wheel Blasting Equipment Applications

We also offer wheel blast equipment to prepare surfaces for painting and finishing. With our abrasive media, you can thoroughly clean the materials you’re working on for smoother paint applications and finishing processes. We recommend implementing this solution for projects such as:

- Deflashing: Remove residues from your project’s surface for clean materials that promote the best results.

- Scale removal: Fully remove scale and smooth out the surface you’re working with for an enhanced appearance.

- Paint and coating removal: Strip old coatings from your project material to prepare for fresh finishing applications.

- Rust removal: Remove rust and other contaminants from corroded surfaces to protect your material’s durability and service life.

- Shot peening: Improve performance, encourage strong bonds between materials and highlight surface defects with shot peening.

Contact Finishing Systems for Your Abrasive Equipment Needs

At Finishing Systems, we are the undisputed experts when it comes to abrasive and sandblasting equipment. If you need reliable abrasive equipment for finishing applications in your business, you want Finishing Systems. You won’t find anyone in the industry with better sand or air blast equipment than us.

To find out how you can order our high-quality abrasive equipment for your business, get in touch now.